BERLUCCHI 2021: 60 YEARS OF BERLUCCHI, 90 YEARS OF FRANCO ZILIANI AND AN INCREASINGLY GREEN COMPANY

A few weeks ago Franco Ziliani turned a venerable 90 years old. As a birthday present, his employees gave him a bottle of Piper Heidsieck.

These were the bubbles that inspired a young winemaker, more than 60 years ago, to recreate similar wines in his own homeland, in the northern Italian region of Franciacorta.

This desire led to a collaboration with Guido Berlucchi, with whom Ziliani shared a great friendship and mutual respect. Thanks to their friendship, their wine-making partnership officially got underway in the early 2000s. When the young winemaker first felt the tingles of inspiration, it was thanks to the partnership with the nobleman of the Lana de’ Terzi family, hailing from Brescia, plans to craft Franciacorta-based wines were soon underway.

Indeed, it was to Franco Ziliani that Guido Berlucchi turned to to guide the development of his “Pinot del Castello,” which would eventually become Pinot di Franciacorta, and would most importantly, have bubbles, following the French version.

The winery staff relates the Sir Ziliani was personally moved by the gift, and it’s certainly understandable considering the sea-changes he effected. Least of which was the development and creation of an entire wine region, Franciacorta, which before his vision, was anything but a wine region.

Although the La Palta restaurant, captained by experienced Isa Mazzocchi, is in a different gastronomically-focused region, the dedication and devotion to her land is just the same love Ziliani has for his Franciacorta. Read Isa Mazzocchi Inspires a New General Store in Italy to learn more.

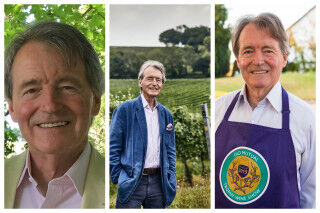

Today, the winery is managed and overseen by Ziliani’s three children, Arturo, Cristina, and Paolo. With their foresight, an increasing amount of attention has been given over to focusing on sustainability.

The winery’s first sustainability report was presented in November 2020, with work underway on the next edition of the report. The data collected reflects a local viticulture that is increasingly in tune with the delicate local environment. Why could this be? One analysis is that the winery is located in the heart of a province and a region with a strong manufacturing-industrial tradition.

Also weighing on this fruitful partnership, as Arturo Zaliani noted, is the fact that the Franciacorta wine sector was primarily responsible for “rescuing” 3,000 hectares of local terrain.

There’s a lot of talk about eco-friendly wines, but what about the people who work with and in the world of wines? Is the playing field equal for women and men in this specialized craftsmanship-focused environment? Check out Is Inclusivity the Real Deal for Women in the World of Wine to learn more.

BERLUCCHI’S ECO-FRIENDLY CONTRIBUTION TO FRANCIACORTA

The report was developed with the consultancy of Ey Sustainability, with the collaboration of LifeGate. The data reflects the efforts the Berlucchi winery has made in the direction of sustainability.

The statistics prove it: to obtain 1 litre of Metodo Classico wine, 2.8 liters of water are needed. 70% of the winery’s waste is immediately recycled, with 20% of all electricity needs met by the generation of energy through photovoltaic panels.

Out of 85 hectares of total vineyard property, 3 hectares are cultivated with Erbamat, an indigenous Franciacorta varietal. This vine is considered a strategic grape, as it confers a specific acidity to the Brescia-area denomination. Its role has become so fundamental, the denomination regulations have been rewritten to include a 10% utilization proportion.

What is so striking about these data is how they reflect the balance between a growing company with an international outlook, and their ability to contain the damage to local environmental assets that help their wines become what they are. In other words, to be successful, one doesn’t necessarily need to simply exploit the land, a successful company can also safeguard their lands.

And as agronomist Diego Cortinovis explains, this is no small undertaking. After all, we’re talking about 85 hectares of property, to which we can add 450 partner winemakers, 101 employees, and 98% of local suppliers.

How did Berlucchi make its way in the first place into the Franciacorta area? Read Berlucchi: An all-Italian story of inspiration, passion and ingenuity today for some background info on this most impressive winery.

Positive trends in agricultural practices are indicating an rise in sustainable methods, ranging from organic fertilization to grassing, from green manure to biological control.

Some of the finest initiatives include welcoming back the bees. These minute creatures have taken up residence amongst the rows of the oldest vineyard of the company, the one around the castle of Borgonato.

Here we can also find 3 hectares of Erbamat. Thanks to the presence of the bees, the area has been replanted with several different varieties aromatic grassy essences and flowering plants.

The use of copper is being examined too, with alternatives already being tested. Seaweed, one alternative, is believed to naturally stimulate the plants’ defensive capacity.

If you’re already considering a visit to Franciacorta and feeling inspired by Berlucchi’s amazing approach to wine-making, you might want to visit an area specialized in wine-making all the way back when…..Renaissance was all the rage. Consider a stop in Florence, home of the always eco-friendly Chianti wines. Read Florence: 100% Art and Culture, but with a wine-spin for more inspiring ideas.

Also in testing phases are the use of satellite technologies. These are believed to be helpful in detecting different levels of chlorophyll in the vines. These levels are indicative of different ripening times, and consequently, where a bit of human help could be useful.

The Compost Spreader is also being tested. This machine distributes natural fertilizer where it is lacking.

All in all, we could say a harmonious system of sustainability. The winemakers are proving that listening to the needs of the environment pays off, in a process of what we’d call precision viticulture.

ZERO IMPACT AS GOAL EVEN IN CELLARS

Enologist Ferdinando dell’Aquila goes over the basics of Metodo Classic wine production with us, following the Berlucchi method. As we learn about the process, it’s impossible to not see the complexity of reducing damaging environmental impacts during the management of the cellar and production facilities.

It’s possible to achieve, but requires tremendous financial investments. Lixke having a line of 8 French Coquard presses, such an unique feature that not even French wineries in the Champagne regions can follow. The presses continue the detailed and precise work that begins in the vineyard itself.

While the eco-friendly approach in wine-making is fundamental, an eco-friendly approach in eating is equally rewarding. Seasonal consumption can play a big role in this, so don’t miss Seasonality Makes a Comeback with On-Demand Fruit + Vegetables for lots more info on this theme.

The winery has no sorting table on the premise, as they don’t ensure the grapes’ full integrity. The selection of the grapes actually happens directly on the vine.

Once the grapes arrive in the cellar, they’re pressed and separately vinified. The 8 Coquard presses can process up to 30 hectares per day. One special feature of the Coquard press are its inclined plates. These favor the rapid descent of the grape must, which has been clarified already thanks to this first natural filtration process.

Each movement of the Coquard press calls for reference parameter readings, like sugar levels, total acidity, and pH. These readings are analyzed, and the pressure exerted onto the grapes by the Coquard presses can then be modified accordingly.

The must then arrives to 4 individual tanks, and is divided according to the quality of the must. Following clarification in additional refrigerated tanks, the next step is the vinification process.

From start to finish, it takes 4.5 hours for a complete pressing cycle to conclude, as the machines have incredibly delicate, slow pistons.

Most importantly, what does Berlucchi taste like? Want to know some feedback from a true fine Italian wine expert? Join Filippo Bartolotta, in Berlucchi's 61 Nature: stunning wines result from traditional method shift in Franciacorta and learn all about Berlucchi today!

Additional separation processes will be done to the liquid later in the cellars, following a series of tastings. At this stage, the musts are further separated into different tanks.

At no point does the wine undergo malolactic fermentation, unlike many other wines. This is a conscientious decision that prevents the wines from experiencing “induced softness.” The wine makers instead focus more on the perpetuelle method, which consists of a dynamic wine creation process where blends of multi-vintage wines are added to the wines that will arrive in the future.

Keep up the good eco-friendly work by shopping smart too. Learn more about brands with your interests at heart, and support your local producers while you shop. The Consumer Brand - Hear about this EU food movement? breaks it down for us.

Don't forget to register for Mamablip's weekly newsletter for updates on all the exciting newest Mamablip Blog articles, recipes and other wine news from Italy.